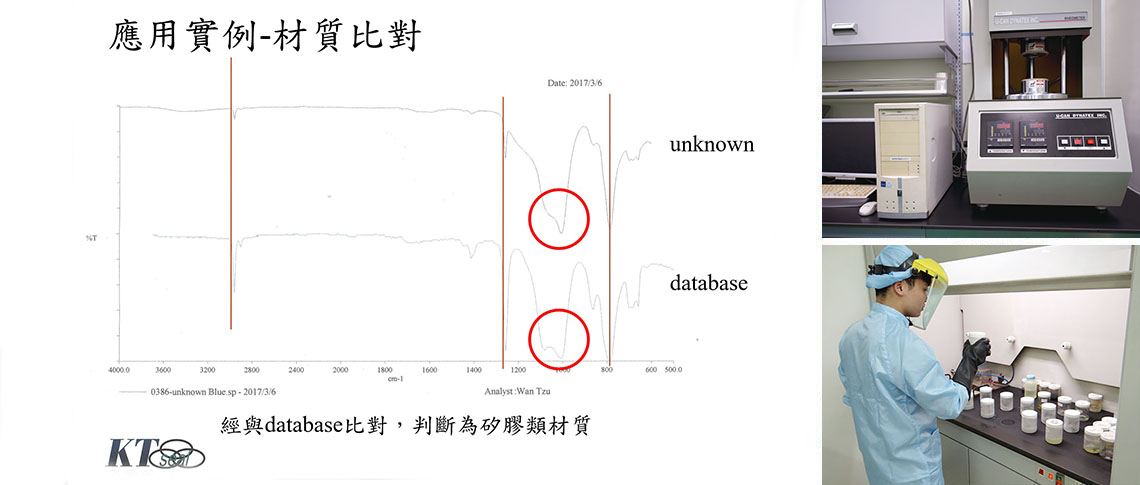

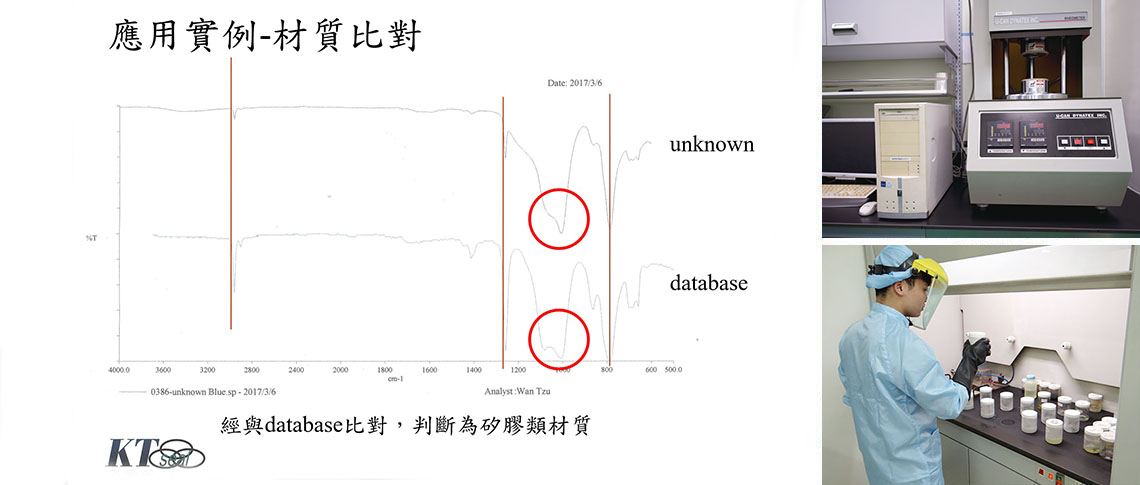

Testing and analysis of mixture and material

Ktseal can test and analyze the mixture and material, and maintain a totally qualified analysis lab by cooperating with the supplier of raw material. This lab, recognized by both Taiwan Laboratories Association and USA Laboratories Association, will accept strict training and testing every year; the company is able to make FTIR, T.G.A and OVEN for the rubbers and test the hardness, pressure/tension, compression set and others.

Manufacture procedure

The main production base and focus of KTseal is located at Hsinchu industry park where manufacturing industry is very developed, and the company has the workshop covering an area of 10,000 sq ft. The high-quality seals are directly supplied to those customers manufacturing high-quality products in Taiwan and the global, and perfluoroelastomer products are manufactured in the clean room by our company. All Ktseal manufacture equipments can make full use of the elastomer manufacture capacity through the production scheduling, and the company can manufacture various products within the same production center and ensure the product stability.

Manufacture equipment

KTseal specifies several steps to manufacture rubber sealing products with its equipments. At first, it will purchase raw materials from world-wide manufacturers. And then the received goods will be checked by the company lab to see if they meet our quality requirements. The equipments used by the company can manufacture those products of various specifications. Various compression molding equipments and latest injection molding technique are included. All manufacture equipments and tools in KTseal comply with elastomers standards.